ISO8442-5

Sharpness Longevity International Standard.

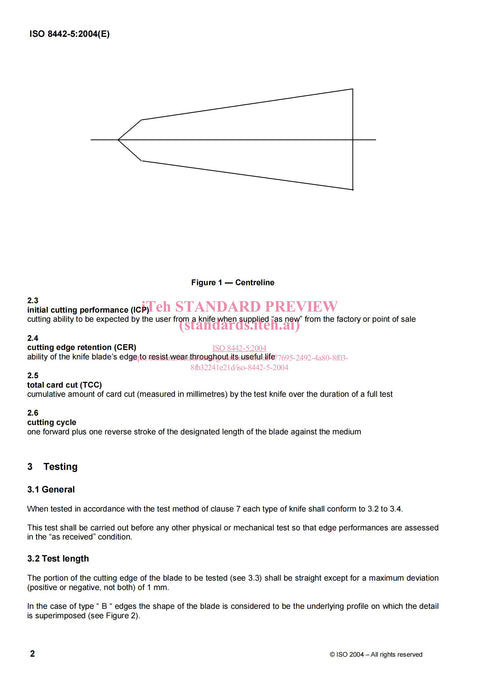

This European Standard specifies the sharpness and edge retention of knives which are produced for professional and domestic use in the preparation of food of all kinds, specifically those knives intended for hand use. Powered blade instruments of any kind are excluded. Generally these types of knives are manufactured with blades of either plain edge design or with edges incorporating particular features to enhance or optimize aspects of cutting ability.

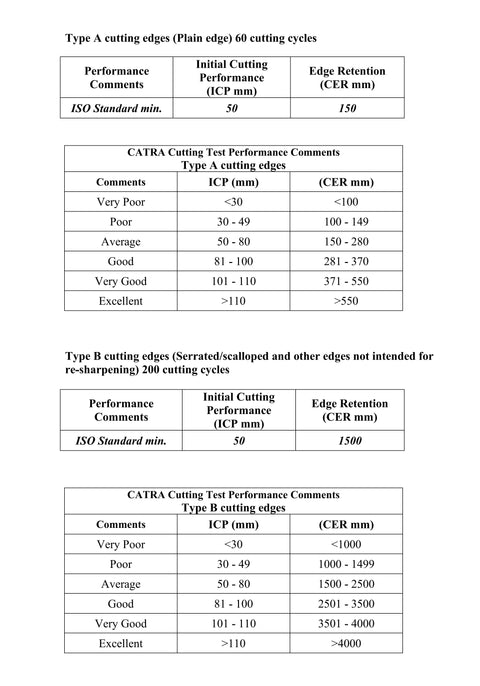

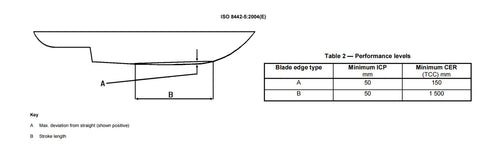

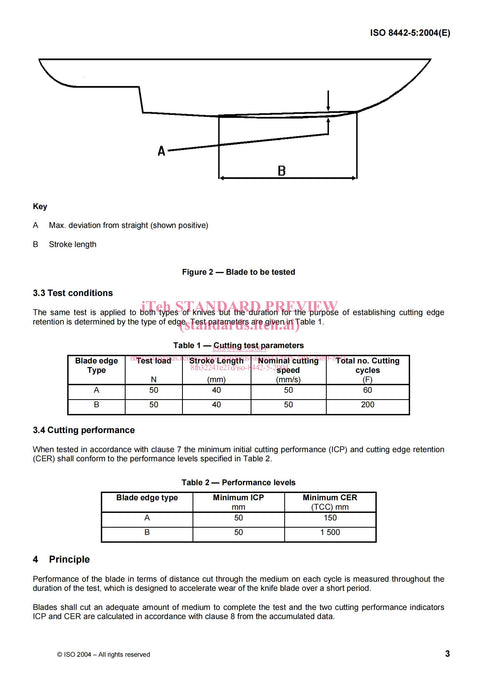

The following two types of knife blade are suitable for the cutting test:

- Type A edges: Cutting edges which can be resharpened by the user and edges with a pitch greater than 1 mm;

- Type B edges: Cutting edges which are not intended to be resharpened on a steel.

- Clearly, our Chef's knives and Nakiri Knives belong to Type A cutting edges. Bread Knives belong to Type B cutting edges.

The Butterfork Sharpness Longevity Test Results

A great knife should stay sharp right? No one on our team wanted to volunteer their arms to chop for thousands of hours. So we get some machines to help out.

Blade Cutting Testing Machine by C.A.T.R.A.

C.A.T.R.A., the Cutlery and Allied Trades Research Association based in Sheeld, England, developed a machine which can objectively test and measure the sharpness and durability of knife blades. Many organizations currently send knife samples to them for testing and evaluation. We, at Butterfork, now possess two of these machines which are used to test and monitor the performance of Butterfork, knives to keep the highest quality at all times.

The tests are conducted twice: once after the blade sharpening process at our factory and the second time at our export department before overseas shipment. By this means we can obtain undeniable objective information on the relative sharpness and performance of our knives, as produced by our factory, and after re-sharpening by various method.

The results speak volumes.

Methodology

The knife is fixed in the machine and the blade is mounted in a position with the edge vertical. The blade is moved back and forth whilst a pack of special testing paper is lowered onto the blade. The blade cuts through the paper and the sharpness is then measured.

Two measurements are produced:

- Initial Cutting Performance (ICP)

This measurement is based on the rst 3 strokes, which represents the

cutting ability or the sharpness of the blade. - Cutting Edge Retention (CER)/TCC

This is measured by conducting over 60 strokes, which represents the life of the blade.

These two measurements are produced and recorded by a computer for each of the knives tested.

Chef's Knives

When ICP > 110 mm and CER > 550 TCC mm, Sharpness Longevity is rated as Excellent. Our chef's knives far exceeds these Excellent testing standards.

- Initial Cutting Performance (ICP): 139.0 mm

- Cutting Edge Retention (CER): 714.7 TCC mm

Nakiri Knives

When ICP > 110 mm and CER > 550 TCC mm, Sharpness Longevity is rated as Excellent. Our Nakiri knives far exceeds these Excellent testing standards.

- Initial Cutting Performance (ICP): 132.0 mm

- Cutting Edge Retention (CER): 731.2 TCC mm

Bread Knives

When ICP > 110 mm and CER > 4000 TCC mm, Sharpness Longevity is rated as Excellent. Our Bread Knives far exceeds these Excellent testing standards.

- Initial Cutting Performance (ICP): 129.4 mm

- Cutting Edge Retention (CER): 4660.1 TCC mm

CATRA Cutting Test to ISO 8442-5

| MAKER | W*STHOF | GL*BAL | GL*BAL | GL*BAL | BUTTERFORK | BUTTERFORK | BUTTERFORK |

|---|---|---|---|---|---|---|---|

| KNIFE | GOURMET Santoku | SANTOKU knife | Vegetable knife | Cook knife | Purest Chef's Knife | Purest Bread Knife | Purest Nakiri Knife |

| PRICE | $100.00 | $129.95 | $129.95 | $159.90 | $109.99 | $109.99 | $109.99 |

| TEST | Factory sharpened | Factory sharpened | Factory sharpened | Factory sharpened | Factory sharpened | Factory sharpened | Factory sharpened |

| ICP | 104.9 | 106.4 | 118.8 | 127.7 | 139.0 | 129.4 | 132.0 |

| TCC | 476.6 | 441.3 | 617.1 | 781.5 | 714.7 | 4660.1 | 731.2 |

Learn More About ISO8442-5

Sharpness Longevity International Standard.

This document (EN ISO 8442-5:2004) has been prepared by Technical Committee CEN /TC 194, "Utensils in contact with food", the secretariat of which is held by BSI, in collaboration with Technical Committee ISO/TC 186 "Cutlery and table and decorative metal hollow-ware".